By integrating the 3D design system, CNC programming technologies, production, and storage systems with our corporate information system, we have created a powerful data and communication platform. This system provides optimal support for our sales, purchasing, financial, technical, and logistics operations. The integration process includes active collaboration with our business partners to link our information systems, thereby promoting mutual efficiency and facilitating cooperation.

.jpg)

We will be happy to advise you on a suitable solution

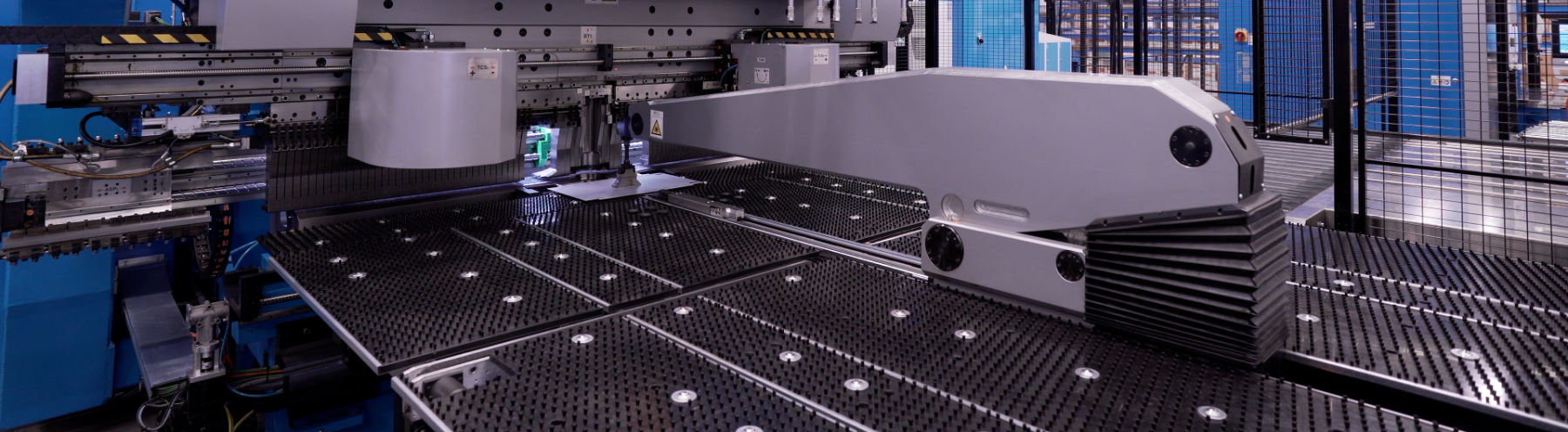

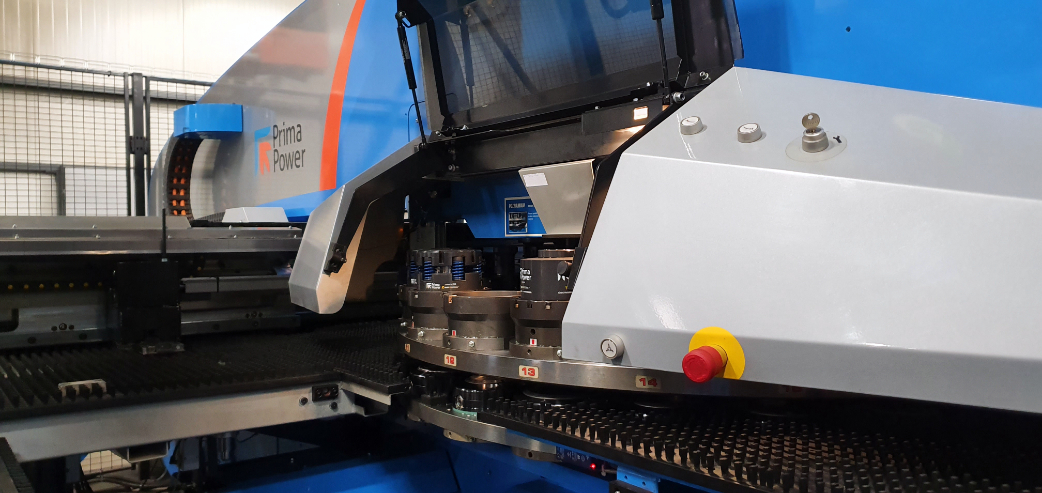

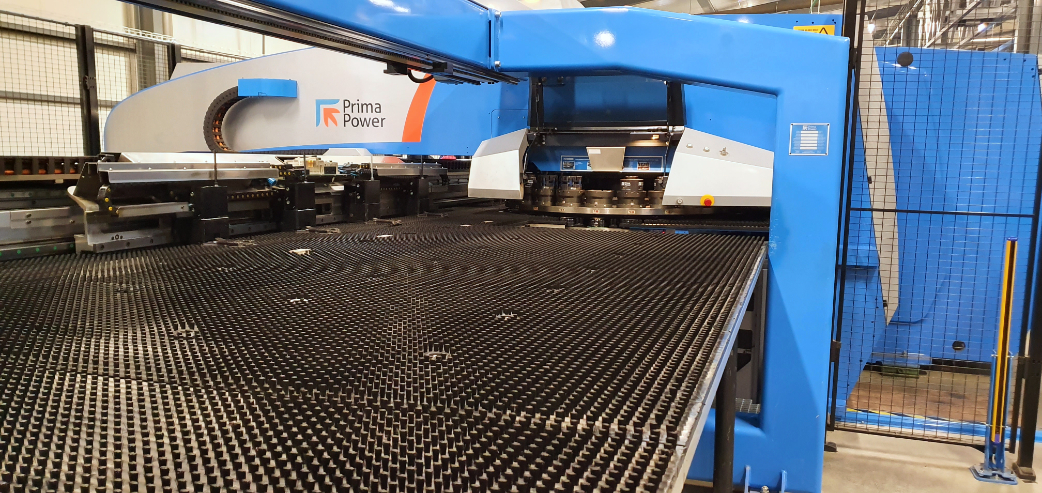

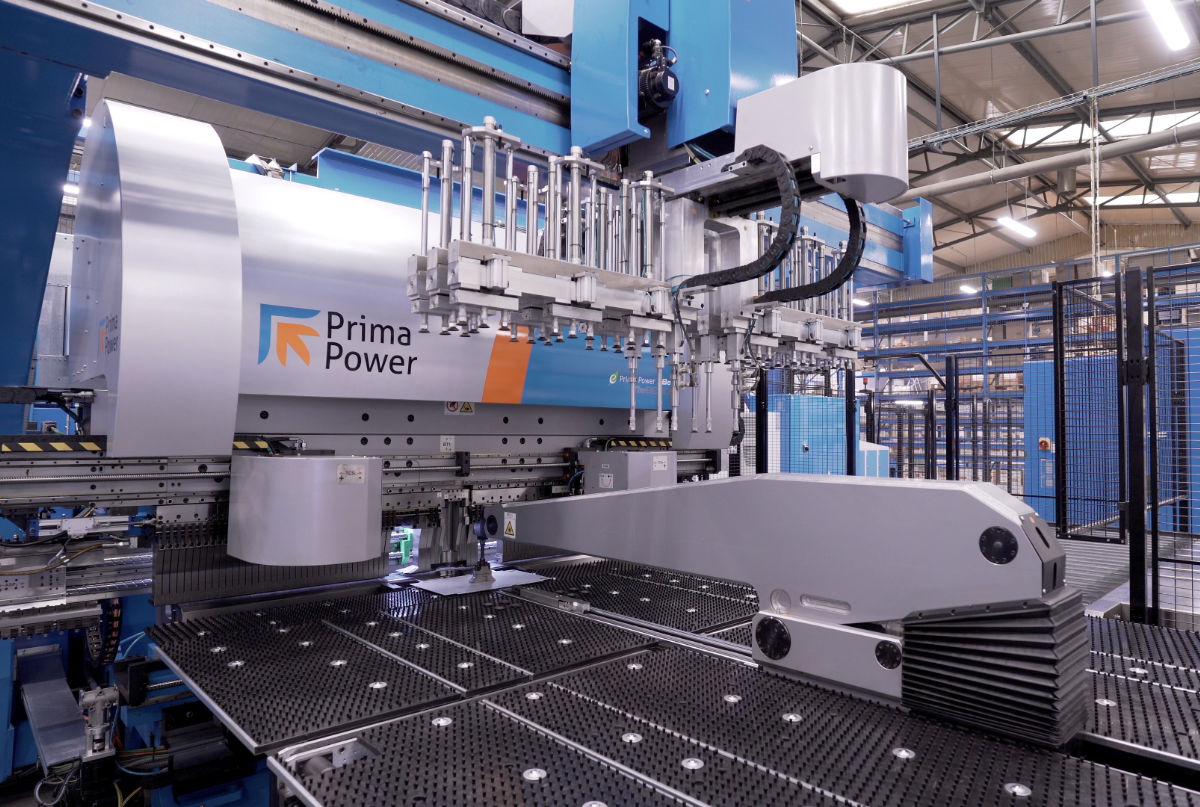

The basis for the high quality and precision of our products is the efficient use of Prima Power PSBB robotic production lines, which are directly connected to our Prima Power NT automated warehouse. This warehouse plays a dual role. It supplies the production lines with material and also serves as a buffer warehouse for work-in-process parts. This synergy enables precise time coordination between the processing of parts and their just-in-time delivery to other production operations, maximizing production flow and minimizing downtime.

.jpg)

Our digital transformation strategy involves more than just streamlining the transfer of data between the technologies used and the information system. Our workplaces are equipped with production terminals that are integrated into our ERP system, creating a comprehensive communication platform for our employees. These devices do not offer only instant information on the plans and documentation required for each workstation, but also allow for the two-way exchange of data regarding ongoing operations. They provide information on the quantity and location of materials and parts needed.