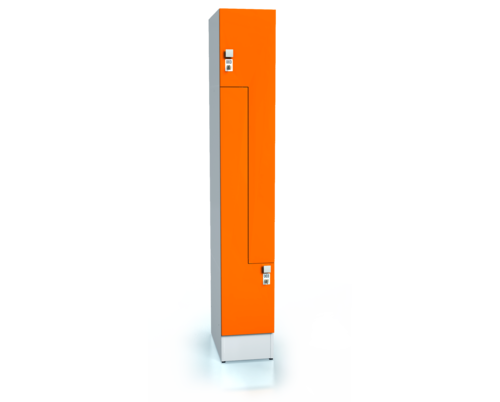

Premium Garment Lockers with Overlay Doors

For textbooks, sports equipment, work clothes and anything else you need to store safely. Steel sheet with increased strength can reliably stand up to the demanding conditions, to whicha it will probably be exposed, especially in the school environment. In practice, this is taken care of by a newly profiled frame structure, which provides higher resistance to forcible pushing of the door into the body and, at the same time, forms a rigid support for the security bolt of the lock.

Premium lockers ALFORT AD 1920 x 300 x 5...

F3S 30 1 1 S AD

Premium lockers ALFORT AD 1920 x 600 x 5...

F3S 30 2 1 S AD

Premium lockers ALFORT DD 1920 x 300 x 5...

F3S 30 1 1 S DD

Premium lockers ALFORT DD 1920 x 600 x 5...

F3S 30 2 1 S DD

Divided premium lockers ALFORT DD 1920 x...

F3S 30 1 2 A DD

Divided premium lockers ALFORT DD 1920 x...

F3S 30 2 2 A DD

Divided premium lockers ALFORT AD 1920 x...

F3S 30 2 2 A AD

Divided premium lockers ALFORT AD 1920 x...

F3S 30 3 2 A AD

Premium lockers Z-shaped doors ALFORT AD...

F3S 30 1 Z S AD

Premium lockers Z-shaped doors ALFORT AD...

F3S 30 2 Z S AD

Premium lockers Z-shaped doors ALFORT DD...

F3S 30 1 Z S DD

Premium lockers Z-shaped doors ALFORT DD...

F3S 30 2 Z S DD

Yet we have not overshadowed any of the other features that our lockers are proud of at the expense of the design. It is also worth mentioning the generous storage space with a volume of 245-330 l. Our high-quality lockers can be also placed in humid areas. In this case, we recommend ordering galvanized sheet metal treated with exterior powder paint. We supply door hinges for this variant with a damped closing mechanism made of stainless steel.

Locking systems

Locking systems