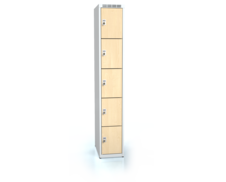

Cabinets with Lockable Boxes

Relieve your customers and employees of their worries and let them concentrate on work or fully enjoy a moment of relaxation. Our high-quality cabinets with lockable boxes safely store every little thing you need. As usual, they have a durable frame and modern design.

Cloakroom locker with three lockable box...

L3M 30 1 3 O

Cloakroom locker with twelve lockable bo...

A3M 30 3 4 O

Cloakroom locker with fifteen lockable b...

L3M 30 3 5 O

Cloakroom locker with fifteen lockable b...

D3M 30 3 5 O

Cloakroom locker with ten lockable boxes...

L3M 30 1 10 O

Cloakroom locker with three lockable box...

D3M 30 1 3 O

Cloakroom locker with twenty lockable bo...

L3M 30 2 10 O

Cloakroom locker with thirty lockable bo...

L3M 30 3 10 O

Cloakroom locker with four lockable boxe...

L3M 30 1 4 O

Cloakroom locker with six lockable boxes...

A3M 30 2 3 O

Cloakroom locker with ten lockable boxes...

L3M 30 2 5 O

Cloakroom locker with five lockable boxe...

D3M 30 1 5 O

.jpg)

You can lock the cabinets with a cylinder lock or a swivel safety locking device. At an extra charge, we can equip the cabinets with coin deposit locks, code mechanical or electronic locks. You can choose from three product lines, differing from each other by the door frame, level of security and the range of standard equipment.

Model lines

Model lines Locking systems

Locking systems