Changing Room Equipment

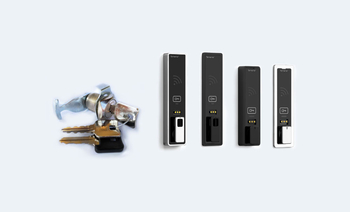

Our high-quality metal cabinets combine tradition with modern technologies. Products designed for equipping changing rooms are an important pillar of our product portfolio, and we therefore pay special attention to them. Our experts regularly assess the possibilities of innovations that would improve their useful properties and the level of overall safety.

.jpg)

And what will happen if there is space for innovations?

Our team of specialists will formulate a proposal for modernization. Then we will start its development and production. All of this will take place on the premises of our own smart factory.

Your visions and wishes are crucial for us. Therefore, we have included several model lines in our catalogue. Each of them responds to specific requirements regarding this type of project. Depending on its complexity, you can choose classical lockers, lockers with lockable boxes, premium lockers or cabinets with glass doors. Our garment lockers will fit perfectly into your interior thanks to the precisely calculated dimensions and design. We can play with their shape and colour. And we can enhance them with a whole number of other accessories.